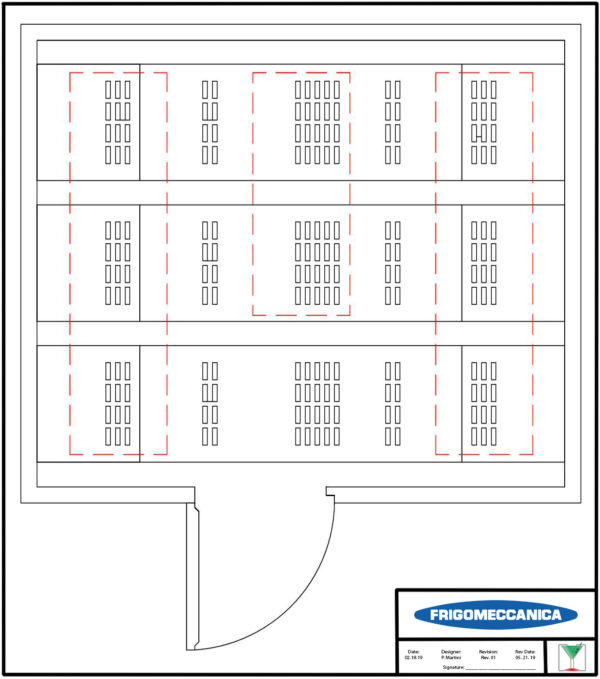

Frigomeccanica Custom Salami Production Rooms

If you are making salami, you know how many hours go into a single recipe. Adjusting salt content, changing spice ratios, and finding the right starter culture all add up quickly. However, once the salami maker moves to the next level of production, you’ll need a custom room. You may become frustrated designing a room that fits all your specific needs.

You may be asking yourself:

- How many different products do I want to make?

- Do I need to bring water to the room?

- How much of each product am I going to make?

- Do I have a nearby drain to connect to?

- How many rooms do I need to make all this product?

- Where will the condensing unit go?

- How do I configure the system to fit into a limited space?

- Do I need a clean room?

Martini Equipment has been designing and installing Frigomeccanica custom salami production rooms for the salami curing process for 25 years. Since 1995, we have partnered with Frigomeccanica, Italy’s leader in medium to large custom systems. Located in Parma, the home of the famous Prosciutto di Parma and Parmigiano-Reggiano, their know-how for building fermenting, drying, and curing/aging rooms dates back to 1962. Many countries worldwide have adopted their technology.

Since the mid-90’s, we’ve helped clients throughout the Americas and installed over 50 rooms. Some started with a medium size room and others added to an existing one to increase production.

Our specialists will work closely with you to understand the scope of your project and design the ideal Frigomeccanica custom salami production room. Once in place, we can help with specific production information, using our access to leading industry consultants. Regardless of your product or its quantity, we can create the perfect solution for all your needs.